Introduction

The use of RFID technology as a modern data collection solution has steadily increased year by year, and the global RFID market is expected to be close to US$32 billion by 2023. The growth of RFID is mainly due to its versatility as a solution, the potential return on investment of feasible applications, and the relative ease of use after installation.

RFID used to be mainly used to open doors and track animals. From a cost and capability point of view, it is more feasible than ever. Not to mention, the value of actionable data is at the highest level in history. Supply chain, healthcare, manufacturing, and cannabis are just some of the many industries that use RFID technology to operate more efficiently. Even with the recent growth of all industries in RFID and technology overall, there is still room for growth in high-temperature RFID applications-especially applications that require prolonged exposure to temperatures above 150+ C (302+ F).

So, what's the problem with high temperature? Isn't high temperature RFID tags already available?

There are several impressive high-temperature tags on the market (scroll down to see popular high-temperature tag options), but there are also restrictions on which applications are feasible. In order to fully understand the obstacles caused by high temperatures, let us first examine the composition of the RFID tag, how it works, and how it is constructed.

Components of RFID tags

Compared to active RFID tags, passive RFID tags are more commonly used in high temperature applications because they are more cost-effective. The development of passive tags usually starts with three basic components:

Antenna-usually made of conductive metal, metal foil or printed metal ink, the antenna receives and transmits radio signals.

Integrated Circuits-Often called chips or ICs, integrated circuits are about the size of a needle, made of silicon, and are the "brain" of tags that store data.

Substrate-A thin layer of material, usually plastic, that holds the chip and antenna together.

At this stage, another layer of material called "face" is applied to cover the exposed antenna and chip, forming an "inlay." The inlay is either sold to the end user or passed through another stage of development to become a finished label or label. In the case of most high-temperature labels, the inlay is encapsulated by thermoplastic, ceramic or other heat-resistant materials to protect the working components of the label from high temperatures and harsh industrial environments.

How passive RFID tags work?

In short, when the RFID reader generates radio frequency waves emitted through the antenna, the internal antenna of the tag within the range of the reader conducts the energy of the radio wave to the tag chip. The energy of the radio wave activates the chip, and the chip modulates the energy with the tag data and transmits the modulated signal back to the reader and/or antenna.

Problem lies in

The size is usually compared with a needle or a grain of sand. The RFID chip must be fixed on a very thin metal tag antenna so that the energy conducted by the antenna activates the chip and accesses the stored data. The chip is usually soldered to the antenna or connected with epoxy. This combination between the tag chip and the antenna is the most vulnerable part of the tag.

The vulnerability is due to the physical composition of the material used to connect the chip to the antenna. If exposed to high temperatures for a long time, even the strongest epoxy and solder metals will melt. If the adhesive becomes weak, the chip will separate from the antenna, rendering the tag useless.

High temperature takeaway

These two terms are the key to evaluating high-temperature labels:

Operating Temperature-The temperature range within which the RFID tag can work normally during its lifetime.

Maximum exposure temperature-the highest temperature that an RFID tag can withstand without affecting the structure and/or performance of the tag.

By maintaining the highest exposure temperature, the chip should remain in place and the label material will remain intact. Most high-temperature label manufacturers will also include important label exposure intervals based on extensive testing.

If a high-temperature label is exposed to high temperatures, it is important to ensure that the label will not be read until the temperature of the label itself is within the operating temperature range of the label. This is because the material connecting the chip to the antenna may not be solid and therefore cannot conduct radio frequency energy as expected. Attempts to read tags at high temperature levels may compromise the chip's data. After a high-temperature label is exposed to high temperatures, its packaging is designed to maintain the internal structure of the label and to dissipate heat, which helps the label to return to its working temperature.

Tag Specification Example:

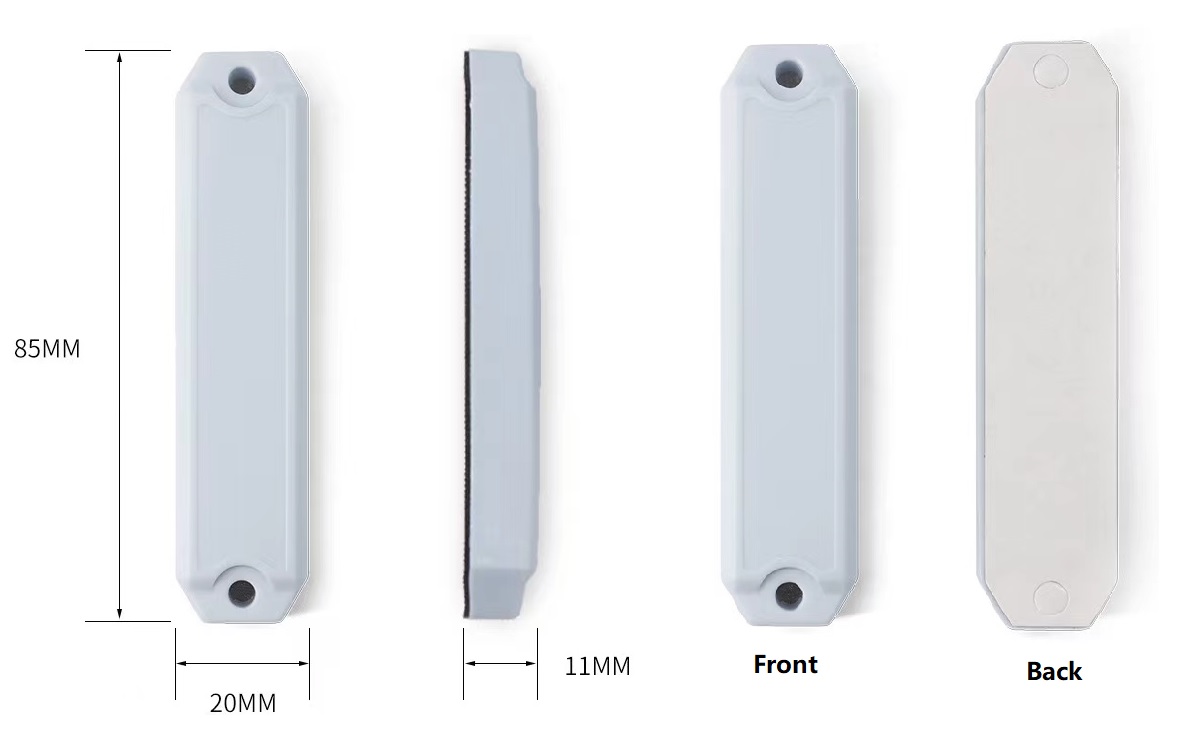

1. High Temperature Resistance Anti Metal UHF Hard Tag

This tag is specially designed to resistant high temperature (under 230°С for 1hours without damage), chemicals, pressure and torsion. The tag operates with UHF chip and can survive in harsh environments,mainly used in industry equipment,manufacturing,automobile manufacturing,oil & gas & mining.

Reliability testing terms and results:

Withstand 230°С for 1 hours continuously without damage.

Passed the 95% alcohol test.

No. 92 gasoline wipe passed.

Material passed SGS certification

Passed Ultrasonic cleaning test

IP68

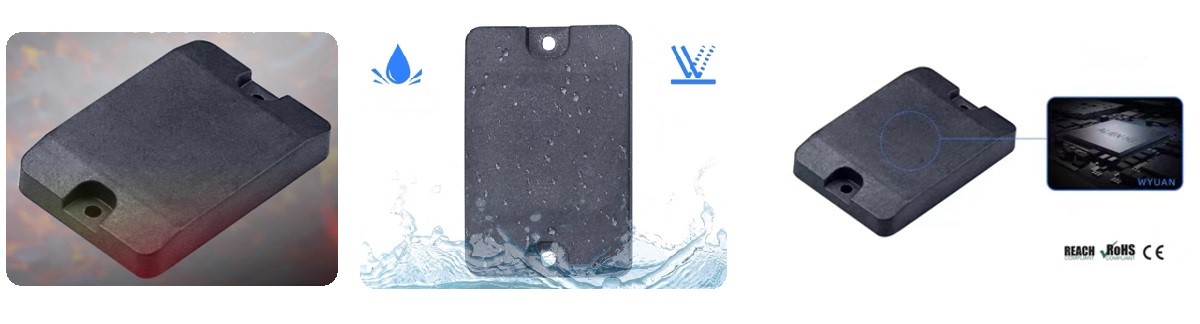

2. UHF ABS On Metal Tag For Pallet Management

This product can be widely used in indoor and outdoor asset management and inspection management. It can achieve good radio frequency performance when installed on metal and non-metal surfaces. The product performance is stable and reliable.Available chips can be Impinj M4QT,R6,etc.

Features:

Rugged tag,can be used in a harsh environment

Impinj M4QT chip or other UHF chip types

Two ways for mounting on assets: adhesive or fixed by screws

Small size: 80 mm×25mm×11mm

High performance: reading distance up to 8 m.

Flexible application: asset management, pallets management, equipment management.