With the continuous advancement of science and technology, RFID technology is increasingly used in industrial production and manufacturing. RFID is used in industrial automation in various industries such as AGV/RGV trolley transportation, three-dimensional warehouses, production lines, material tracking and management, etc. It provides assistance for intelligent automation of industrial production and manufacturing. Below, I will share with you the application cases of RFID technology in industrial production and manufacturing.

1. AGV/RGV trolley transportation

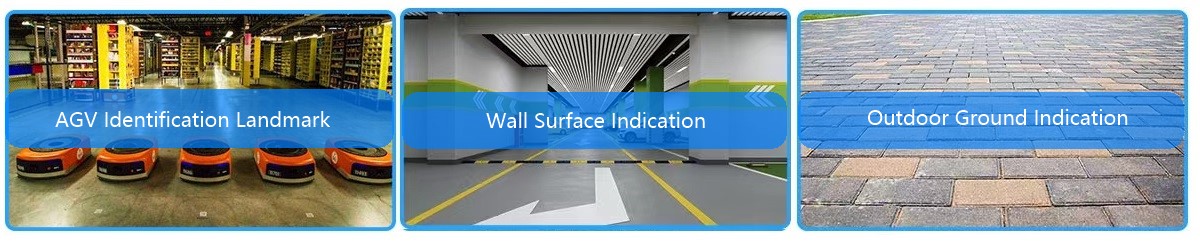

In the industrial production and manufacturing process, AGV/RGV trolley transportation is a common logistics method. However, traditional AGV/RGV vehicles have problems such as low work efficiency and error-prone data collection during transportation operations. In response to these problems, Kezhili RFID has launched a car transportation solution based on RFID technology. By installing an RFID AGV reader on the trolley, RFID landmark tags are installed on the track nodes. When the car is carrying out transportation operations, the reader can automatically identify the label information on the track nodes, perform site positioning and identification of the car based on the labels read on different nodes, and move the car forward, turn, and accelerate based on the information on the node labels. , parking and other status determination, to achieve automated management of trolley transportation, improve transportation efficiency, and reduce manual intervention.

2. Three-dimensional warehouse

The three-dimensional warehouse is an important part of the modern logistics system and has the advantages of high storage density and high degree of automation. However, the traditional three-dimensional warehouse management method often has problems such as difficulty in finding goods and error-proneness. By introducing RFID technology, it is possible to achieve rapid reading and precise positioning of cargo information, improve the efficiency of cargo search and management, achieve first-in, first-out, last-in, last-out, and avoid waste caused by the backlog of goods. Real-time reading of RFID readers can also be achieved Automated updating and management of cargo information reduces manual intervention and error rates.

3. Production line

On the production line, every production link needs to be precisely controlled to ensure product quality and production efficiency. Install RFID tags on the products, and install RFID readers at the nodes of the production line. When the products pass through the RFID readers at the nodes, product information and production status are automatically identified, achieving traceability and real-time monitoring of the production process. Through RFID technology, the production status of the production line can be grasped in real time, intelligent scheduling and management of the production line can be realized, and production efficiency and product quality can be improved.

4. Material tracking and management

In the industrial production and manufacturing process, material tracking and management are crucial. By introducing RFID technology and deploying RFID readers at corresponding workstation nodes in the production line, material information can be quickly read and accurately positioned, and materials can be tracked and managed in real time. By installing RFID tags on materials, readers can automatically identify material information and usage status, achieve precise management and control of materials, and reduce material waste and losses.

5. The use of RFID in industrial automation in various industries

RFID technology has broad prospects in the application of industrial automation in various industries. Whether it is automobile manufacturing, machinery manufacturing, semiconductor manufacturing, electroplating and other industries, automated management and precise control of the production process can be achieved by introducing RFID technology. Through the application of RFID technology, the production process can be intelligent, informatized and digitalized, improve production efficiency and quality, and reduce production costs and human resource consumption.

In short, the application cases of industrial RFID manufacturers in the field of industrial production and manufacturing show that RFID technology can improve production efficiency and quality, reduce production costs and human resource consumption, and realize the intelligence, informatization and digitization of the production process. In the future, with the continuous advancement of technology and the continuous expansion of application scenarios, the application of RFID technology in the field of industrial production and manufacturing will become more extensive and in-depth.