In 2011, Germany first proposed the concept of Industry 4.0.

In June 2013, the General Electric Company (GE) of the United States proposed the concept of the Industrial Internet.

In recent years, the Internet of Things, as a strategic emerging industry, has become the focus of national development, and the Internet of Things industry has continued to develop.

The continuous advancement of ideas and strategies in various countries indicates that the cross-border integration of information technology and traditional industries has become an inevitable trend, all pointing to the core of intelligent manufacturing. Smart manufacturing requires the collection of data from industrial equipment, which is then analyzed and analyzed for use in the next step.

However, in extreme application scenarios such as metal, ordinary UHF RFID tags cannot be used, and data collection faces huge challenges. An RFID flexible anti-metal tag came into being. It is encapsulated in the electronic label with special anti-magnetic absorbing material. It not only technically solves the problem that ordinary electronic labels cannot be attached to metal surfaces, but also can be attached to metal surfaces like ordinary labels. On curved surfaces, it takes on the important responsibility of collecting data in extreme environments like metals

The structure of electronic RFID tags is developing in the direction of lightness, thinness, smallness and softness. In this regard, flexible electronic devices have advantages unmatched by other materials, so the future development of electronic tags in RFID systems is likely to be combined with flexible electronic manufacturing to make the use of RFID tags more extensive and convenient. In addition, it can greatly reduce costs and bring higher benefits. This is also one of the future development directions of flexible electronic manufacturing.

Making low-cost flexible metal RFID tags has two implications. On the one hand, making flexible electronic devices is a beneficial endeavor. Electronic circuits and electronic devices are developing in the direction of "light, thin, small and soft", and the development and research of flexible electronic circuits and electronic devices is more attractive.

For example, a flexible circuit board that can now be produced is a circuit that contains precision wires and is made from a thin, flexible polymer film. It can be applied in surface mount technology and can be bent into countless desired shapes.

Flexible circuits using SMT technology are very thin, lightweight, and have an insulation thickness of less than 25 microns. This flexible circuit can be bent arbitrarily and can be bent into a cylinder, making full use of the three-dimensional volume.

It breaks the traditional way of thinking of the inherent use area, thus forming the ability to make full use of the volume shape, which can greatly improve the effective use density in the current method, and form a high-density assembly form, which is in line with the flexibility of electronic products. development trend.

On the other hand, it can speed up my country's understanding and development process of RFID technology. In the RFID system, the transponder is the key technology. RFID tags are one of the many forms of RFID transponders, and flexible metal RFID tags are more suitable for more occasions. The reduction in the cost of RFID tags will greatly promote the truly widespread application of RFID technology.

The influence of metal objects on the parameters and performance of the tag antenna is mainly reflected in two aspects.

In simple terms, one is the antenna field, and the other is the antenna parameters (eg: impedance, S-parameters, radiation efficiency).

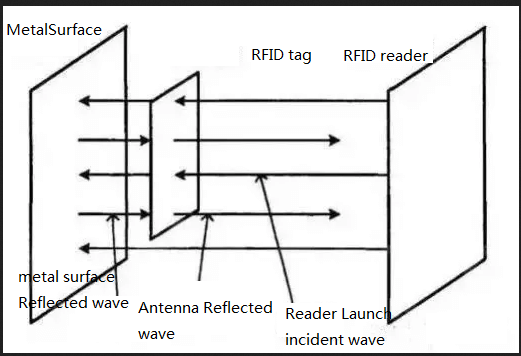

In the field where the antenna works, there are the incident wave emitted by the reader and the reflected wave reflected back from the metal plate. There is a certain phase difference between the incident wave and the reflected wave, which causes the two to cancel each other and make the field strength to a certain extent. weakened. In this way, the tag antenna working in this environment cannot induce enough current to provide energy to the tag chip, so that the tag chip cannot be activated and cannot work.

Therefore, a suitable RFID anti-metal tag is the premise to ensure the application effect of the RFID system.

SunRise Smart can provide a variety of RFID flexible metal-resistant tags. It has the most stable performance among similar products in the market. Thin thickness, good printing effect, the longest reading distance on metal can reach 4~5 meters, price advantage. .Support customization, all labels are 100% tested before shipment to ensure quality. Check the following characteristics:

Ideal for RFID tags on metal surfaces

Ultra-small and ultra-thin, only 1MM thick, suitable for thermal transfer printers,

good printing effect

Slightly bends and conforms to curved surfaces

Long reading distance, metal reading distance up to 5 meters

Supports FCC and ETSI frequency requirements

Can reach IP68 protection level

For more information, please feel free to contact the SunRise sales team: sale@sunriserfid.com